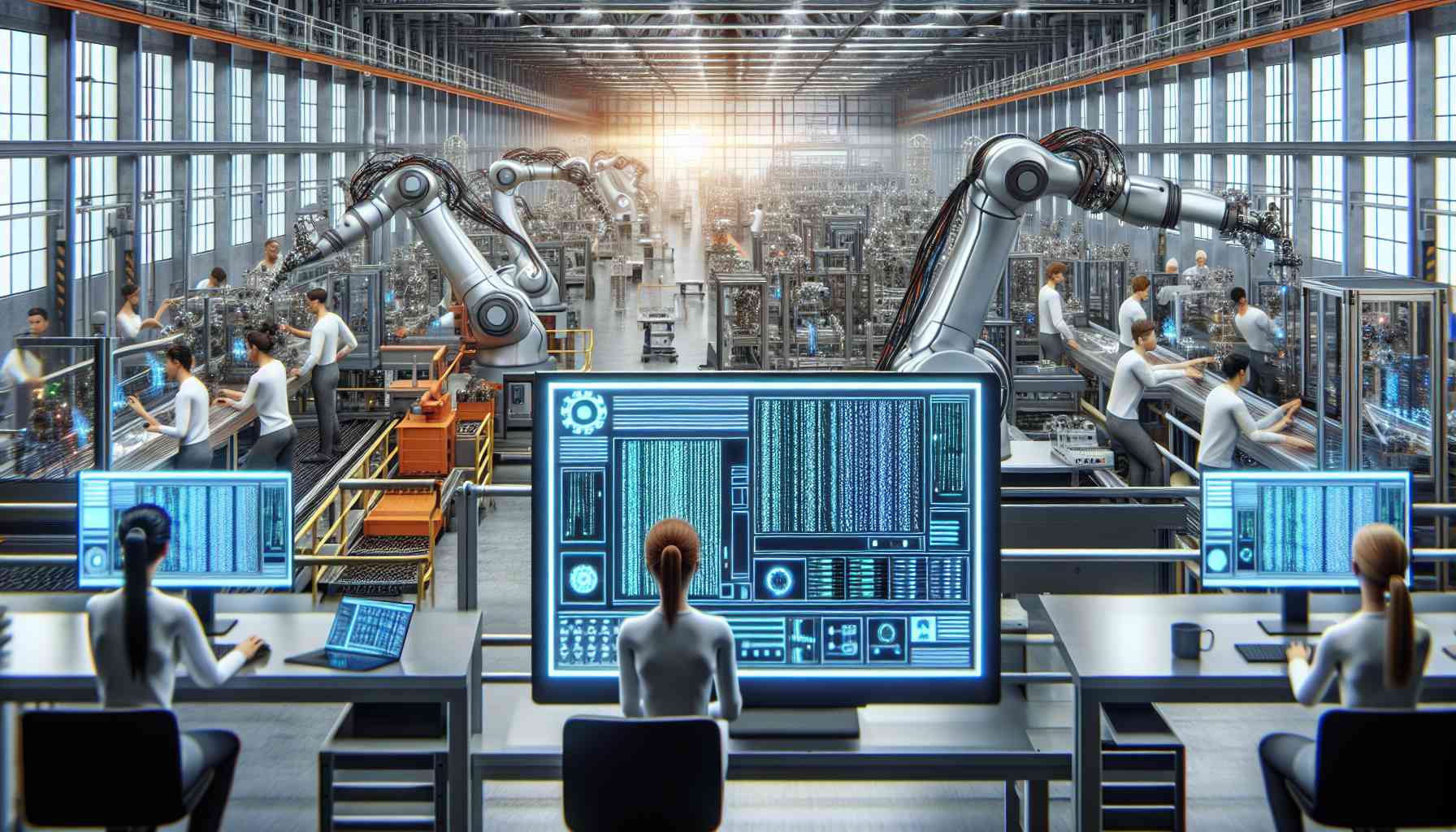

The manufacturing industry is undergoing a significant evolution as it embraces the concept of Industry 4.0. One of the key technologies driving this transformation is Machine Learning (ML). ML applications have become vital for efficient and cost-effective operations in manufacturing. While there are numerous ML applications in this industry, three stand out as game-changers.

Optimizing Supply Chain Management

ML integration in supply chain management automates tedious tasks and allows firms to focus on strategic and business activities. ML algorithms provide precise insights for inventory management, preventing overstocking or understocking. These algorithms also enhance demand forecasting accuracy by analyzing historical data to identify hidden patterns and factors like trends, seasonality, and non-linear dependencies. With accurate demand data, firms can plan for procurement, production schedules, and distribution more effectively, minimizing lead times and reducing the risks of stock-outs or excess inventory.

Streamlining Quality Control

ML plays a crucial role in streamlining quality control processes in manufacturing. ML tools analyze data patterns to detect anomalies and defects in finished products, ensuring that only high-quality products reach the customers. ML also helps maintain quality standards by applying a rule-based approach to detect flaws and ensure consistency and precision. Furthermore, ML enables root cause analysis, allowing firms to identify defects in the value chain and make improvements in specific stages of the production process.

Enhancing Predictive Maintenance

Predictive maintenance is essential in a manufacturing environment to prevent downtime and production or delivery losses. ML tools can accurately forecast incidences, providing teams with advanced notice to prepare and respond effectively. ML algorithms also provide actionable insights for addressing potential issues, recommending maintenance actions based on historical and real-time data. Additionally, ML enables conditional monitoring, allowing for real-time assessment and adjustment of maintenance strategies.

In a rapidly evolving industrial landscape, adopting ML is imperative for manufacturing firms aiming to stay competitive. It enables the optimization of supply chain management, streamlines quality control processes, and enhances predictive maintenance. By embracing ML applications, manufacturers can drive operational efficiency, innovation, and meet the challenges of the modern era head-on.

This article is based on the original source: [Insert source name and link]

The source of the article is from the blog lanoticiadigital.com.ar