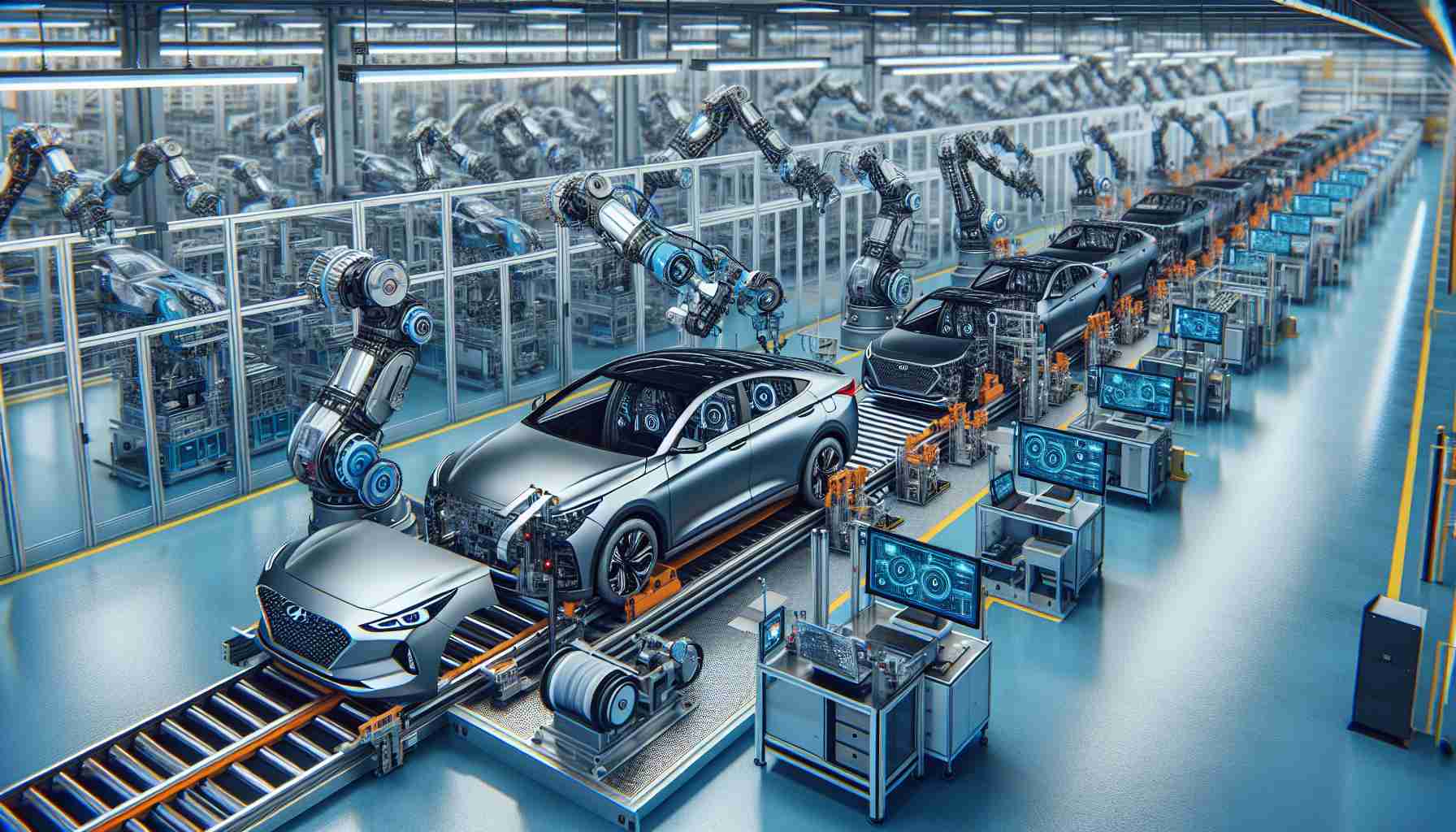

The integration of Artificial Intelligence (AI) and automation has transformed various industries, revolutionizing processes and enhancing productivity. Hyundai Motor India, one of the leading automotive manufacturers, has taken this technological advancement to the next level by incorporating AI and automation into their manufacturing facilities.

Traditionally, automakers have utilized AI and automation to improve customer experiences through services like over-the-air updates. However, Hyundai goes a step further, utilizing these technologies to streamline operations and enhance customer satisfaction with the final product.

Gopala Krishnan CS, the Chief Manufacturing Officer at Hyundai Motor India Limited, explains that their high level of automation ensures a ‘zero defect’ production cycle, guaranteeing that customers always receive a perfect vehicle. By leveraging Industry 4.0 Automation at their Tamil Nadu facility, Hyundai achieves precise body dimensional accuracy through automated 3D scanner systems. This integration of technology allows them to optimize manufacturing processes, minimize errors, and maximize output.

Hyundai’s manufacturing approach revolves around three core pillars: advanced body strength, rigorous testing, and superior quality. These pillars align with the automaker’s global standards, ensuring that every vehicle meets the highest level of excellence. Through digital pre-assembly, robo programs, offline testing, and virtual reality training, Hyundai fine-tunes the development process, leading to faster model development and the ability to adapt to market trends.

Krishnan emphasizes the importance of customer-focused, human-centric innovation. By continuously researching and developing new technologies, Hyundai aims to leverage AI and create smarter, safer, and more sustainable mobility solutions for the future. This approach also fosters an innovative culture among employees, encouraging the generation of new ideas and concepts for future products.

Additionally, AI plays a crucial role in managing market demands. Hyundai’s manufacturing plant in Chennai features body weld lines that can produce multiple models on a single line. This flexibility enables the company to adjust the production rate of specific models based on market demand, ultimately reducing waiting periods for customers.

Hyundai’s commitment to achieving manufacturing excellence involves strategic investments in future technologies. By integrating advanced manufacturing technology, the automaker aims to provide customers with the best possible products and experiences. Their focus on AI and automation highlights Hyundai’s dedication to continuous improvement and innovation.

Frequently Asked Questions

1. How has Hyundai incorporated AI and automation into manufacturing?

Hyundai has integrated AI and automation into their manufacturing facilities to streamline operations and enhance customer satisfaction with the final product. By leveraging Industry 4.0 Automation and advanced technologies, Hyundai optimizes manufacturing processes, reduces errors, and maximizes output.

2. What is Hyundai’s manufacturing approach?

Hyundai’s manufacturing approach is centered around three core pillars: advanced body strength, rigorous testing, and superior quality. They ensure that every vehicle meets global standards, guaranteeing excellence in design and performance.

3. How does Hyundai use AI to manage market demands?

Hyundai’s manufacturing plant in Chennai features body weld lines capable of producing multiple models on a single line. This flexibility allows Hyundai to adjust the production rate of specific models based on market demand, minimizing waiting periods for customers.

4. How does Hyundai foster innovation among its employees?

Hyundai believes in a customer-focused, human-centric innovation approach. Through continuous research and development, they leverage AI and automation to create smarter, safer, and more sustainable mobility solutions. This culture of innovation encourages employees to contribute ideas and concepts for future products.

Sources:

– Hyundai Motor India Limited: [www.hyundai.com](https://www.hyundai.com)

The integration of Artificial Intelligence (AI) and automation has transformed various industries, including the automotive industry. Hyundai Motor India, one of the leading automotive manufacturers, has taken this technological advancement to the next level by incorporating AI and automation into their manufacturing facilities. By doing so, they aim to streamline operations and enhance customer satisfaction with the final product source.

Hyundai’s high level of automation ensures a ‘zero defect’ production cycle, guaranteeing that customers always receive a perfect vehicle. They achieve this through the utilization of Industry 4.0 Automation at their facility in Tamil Nadu. The integration of automated 3D scanner systems allows them to achieve precise body dimensional accuracy. With this technology, Hyundai optimizes their manufacturing processes, minimizes errors, and maximizes output source.

The manufacturing approach of Hyundai revolves around three core pillars: advanced body strength, rigorous testing, and superior quality. These pillars align with the automaker’s global standards, ensuring that every vehicle meets the highest level of excellence. Through digital pre-assembly, robo programs, offline testing, and virtual reality training, Hyundai fine-tunes the development process, leading to faster model development and the ability to adapt to market trends source.

In line with their commitment to customer-focused innovation, Hyundai continuously researches and develops new technologies. Their goal is to leverage AI and create smarter, safer, and more sustainable mobility solutions for the future. This approach fosters an innovative culture among employees, encouraging the generation of new ideas and concepts for future products source.

Furthermore, AI plays a crucial role in managing market demands. Hyundai’s manufacturing plant in Chennai features body weld lines that can produce multiple models on a single line. This flexibility allows the company to adjust the production rate of specific models based on market demand, ultimately reducing waiting periods for customers source.

Hyundai’s commitment to achieving manufacturing excellence involves strategic investments in future technologies. By integrating advanced manufacturing technology, the automaker aims to provide customers with the best possible products and experiences. Their focus on AI and automation highlights Hyundai’s dedication to continuous improvement and innovation source.

The source of the article is from the blog combopop.com.br