A cutting-edge technology event showcased the latest advancements in the industrial sector, offering innovative solutions to revolutionize production processes. Companies debuted state-of-the-art products leveraging artificial intelligence to accelerate digital transformation for businesses in Vietnam, enhancing their competitive edge and fostering sustainable growth.

Introducing the Next Generation Robot: TechROVER-3000

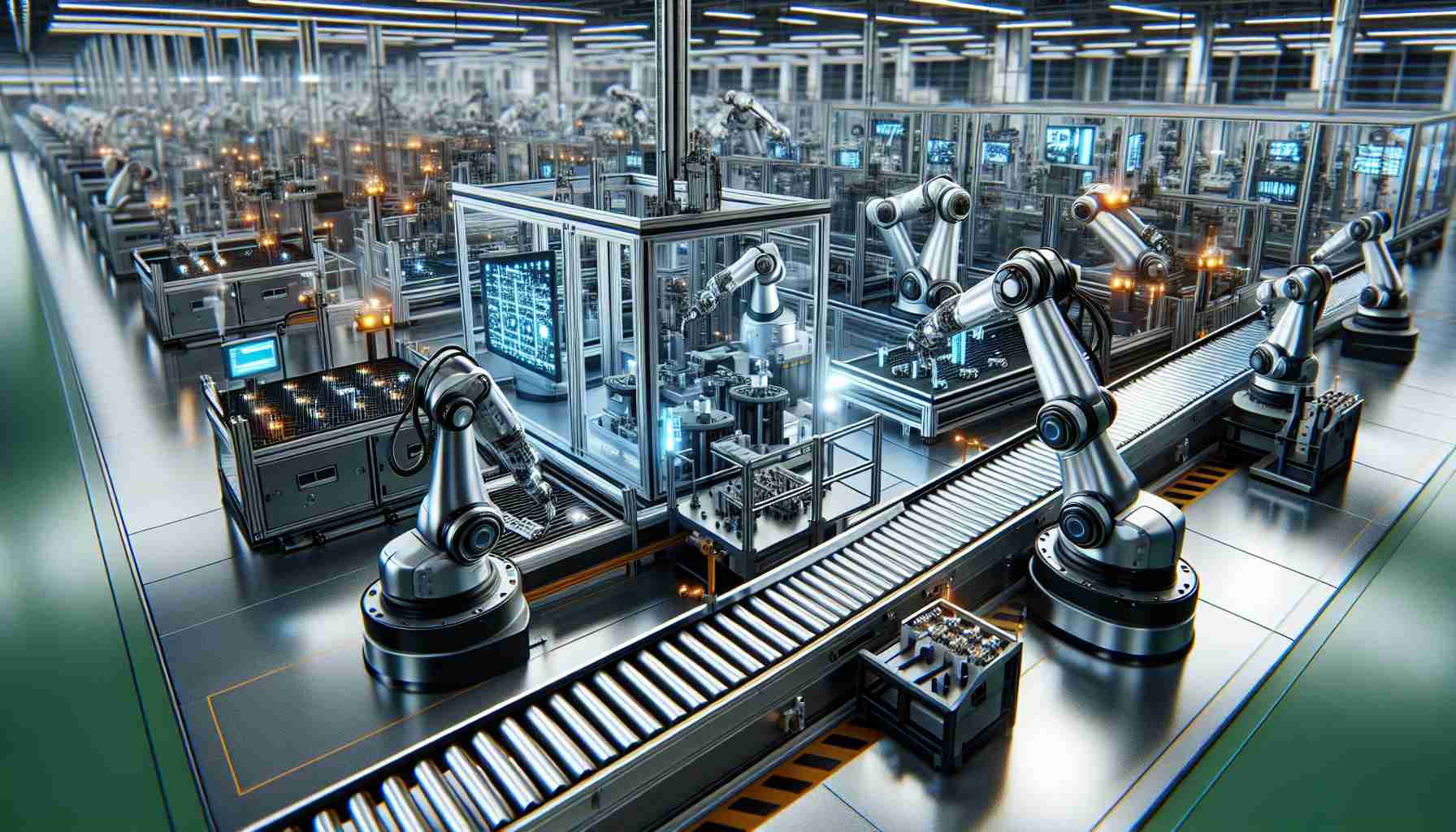

One of the standout innovations presented was the TechROVER-3000, a revolutionary robot designed by local original equipment manufacturer (OEM) TechGenius. This cutting-edge delta robot can swiftly and efficiently handle product transfers between conveyors, boasting Siemens technologies such as the Totally Integrated Automation (TIA) Portal, programmable logic controller (PLC), advanced motion control, industrial edge computing, and robot control solutions. The TechROVER-3000 aims to redefine how OEMs design processes for their machinery, optimizing production and expediting time-to-market.

Virtual Operations Solution Leading the Charge

Furthermore, the integration of virtual and physical realms through the Virtual Operations Solution has accelerated machine testing, reduced costs, and mitigated risks. This innovative approach enables engineers to create a digital twin of physical machines for virtual testing and system optimization before deployment, thereby streamlining product development, enhancing quality, and ensuring safety.

Empowering Transparency and Security with AI

The implementation of the Industrial Anomaly Detection solution, backed by Siemens’ AI technology, promotes transparency regarding asset and data exchange in industrial networks while proactively identifying anomalies and threats. This heightened level of security safeguards operations and data integrity, ensuring seamless industrial processes.

Unlocking Sustainable Success through Digitalization

Siemens Vietnam’s Director of Digital Industries, Mr. Trần Thế Hiển, emphasized how digital and automation solutions are transforming production operations in the food and beverage industry. These innovative advancements pave the way for sustainable development and greater success in business, enabling industries to swiftly meet individual customer demands without compromising quality in the competitive Vietnamese market.

Additional Facts:

– The adoption of cutting-edge technology in production processes has been shown to significantly increase efficiency, reduce errors, and lower operational costs for businesses.

– Industries such as automotive, electronics, healthcare, and aerospace have also embraced advanced technologies like robotics, Internet of Things (IoT), and cloud computing to enhance their manufacturing operations.

– In addition to enhancing productivity, integrating technology in production processes can also lead to improved worker safety and well-being through the automation of hazardous tasks.

Important Questions:

1. How can companies ensure a smooth transition to using cutting-edge technology in their production processes?

2. What are the potential cybersecurity risks associated with integrating advanced technologies into industrial networks?

3. How can businesses balance the cost of investing in new technology with the expected benefits and returns in the long term?

Key Challenges and Controversies:

– One key challenge is the potential job displacement caused by automation and the need for upskilling or reskilling workers to adapt to new roles.

– Controversies may arise regarding data privacy and ownership rights when implementing technologies like AI and IoT in production processes.

– Another challenge is the initial high cost of acquiring and implementing cutting-edge technology, which may be a barrier for small and medium-sized enterprises.

Advantages and Disadvantages:

– Advantages: Increased efficiency, improved product quality, reduced lead times, enhanced competitiveness, potential for innovation and growth.

– Disadvantages: Initial high costs, workforce disruption, cybersecurity risks, technology obsolescence, potential resistance to change from employees.

Related Links:

– Siemens Official Website

– TechGenius Official Website

– Robotics Industry Information