Artificial Intelligence (AI) Initiatives Elevate Production and Worker Safety

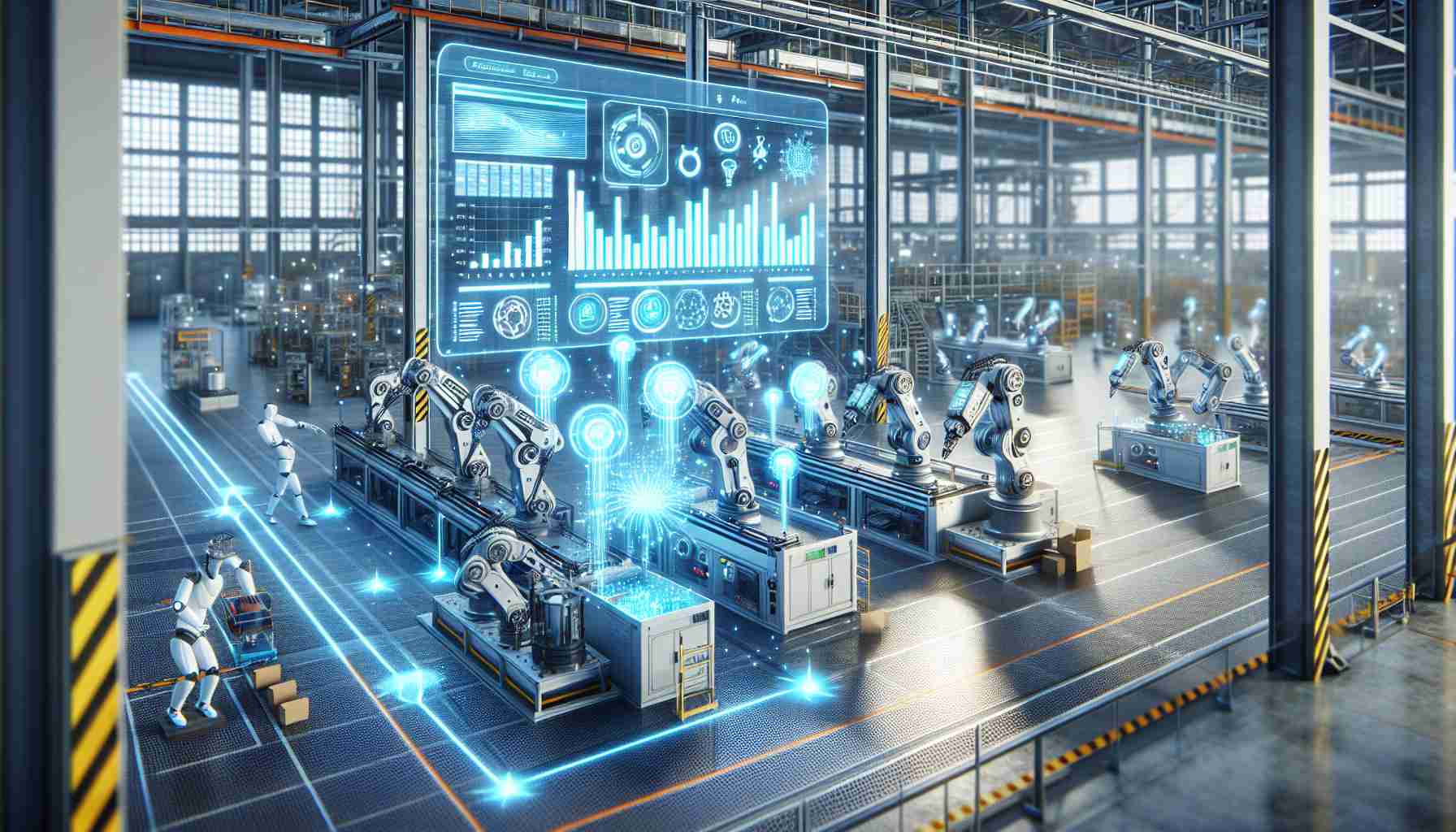

In a world that is quickly digitizing, the emergence of Artificial Intelligence (AI) has brought fundamental changes to how production processes and worker safety are managed. The integration of AI into production lines enhances not only efficiency and productivity but also significantly bolsters the safety of employees. Through its capability to analyze large sets of data and adapt from past experiences, AI introduces groundbreaking improvements in industrial process efficiency.

Industries Reaping the Benefits of AI Applications

Various industries, such as automotive, aviation, manufacturing, and healthcare, are currently benefiting from AI applications. These are leading to increased productivity, improved safety standards, and reduced operational costs. Tailored AI solutions, finely tuned to meet the unique demands of each industry, enable the delivery of high-quality products while mitigating the risk of human errors.

LASIT’s Technological Synergy with AI

In the realm of industrial AI application, laser marking is a prime example where such innovations prove their worth. LASIT, a pioneer in laser system technologies, is effectively implementing AI in marking processes, which allows the customization of laser parameters for different materials. This synergy between laser technology and AI optimizes quality and efficiency while significantly minimizing the risk of defects.

AI’s Role in Personal Protective Equipment (PPE) Development

AI also plays a crucial role in the development of smart personal protective equipment (PPE). These advanced systems, using AI to identify hazards, monitor worker fatigue, and detect falls, not only increase safety but, also support risk management and operational decision-making.

The Industrial Revolution Redefined by AI

The application of AI in industry paints a vision of a future where safety management and production efficiency reach their highest levels, offering innovative tools to streamline processes and elevate work standards. We are at the forefront of an industrial revolution that redefines new realities for the industrial sector, transforming traditional manufacturing methods into more advanced, efficient, and safer processes.

Key Questions with Answers

What are some of the key challenges in implementing AI in industrial settings?

One key challenge of implementing AI in industrial settings is the initial cost and complexity of integrating AI systems into existing infrastructure. Businesses must ensure that their staff are trained to work with new AI tools, which requires additional investment in education and training. Furthermore, there are concerns regarding job displacement due to automation and ensuring that data privacy and security are properly managed in AI applications.

Are there any controversies associated with AI in industrial safety and efficiency?

There are ethical controversies, such as the potential for job displacement as AI systems become more capable of performing tasks traditionally done by human workers. There is also the issue of trust and reliability of AI systems, particularly when it comes to making decisions that could affect workers’ safety. Additionally, the misuse of data and AI biases pose significant concerns.

Advantages and Disadvantages of AI in Industrial Safety and Efficiency

Advantages:

– Enhanced Safety: AI systems can predict and prevent potential accidents by analyzing data and identifying risk factors, leading to safer working environments.

– Increased Efficiency: AI automates repetitive tasks, optimizes production processes, and reduces downtime, dramatically increasing efficiency.

– Cost Reduction: In the long term, AI can lower operational costs by improving resource management and reducing waste.

– Data-Driven Decisions: AI enables better decision-making by providing comprehensive data analysis and forecasting tools.

Disadvantages:

– High Initial Costs: Implementing AI requires significant investment in technology and training, which might not be feasible for all businesses.

– Job Displacement: Automation through AI could lead to loss of jobs, particularly for roles that are routine and repetitive.

– Reliability and Trust: Dependence on AI systems raises questions about their reliability, especially in high-risk situations.

– Privacy and Security: Collecting and analyzing data for AI could lead to privacy breaches and security risks if not properly managed.

Relevant Additional Facts:

– AI can also enhance predictive maintenance in industries, where it can forecast equipment failures and schedule timely maintenance, thereby preventing accidents and ensuring uninterrupted production.

– The use of AI-powered robots and drones for monitoring and inspection can reach places that are unsafe or inaccessible to humans, further improving safety and efficiency.

– There’s growing interest in using AI for energy management and optimization within industrial settings, promoting sustainability alongside productivity and safety improvements.

Related Links

– AI in the broader context of industrial applications: IBM

– Information on smart personal protective equipment (PPE): 3M

– Insights on the ethical implications of AI in the workplace: World Economic Forum

These links are provided to reputable domains that offer additional information related to AI in industrial safety and efficiency.